Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Analysis and Design of Sequencing Batch Reactor Basin for Sewage Treatment Plant by using Autocad

Authors: Jaishankar Gabel, Dr. Rakesh Kumar Pandey

DOI Link: https://doi.org/10.22214/ijraset.2024.62597

Certificate: View Certificate

Abstract

The objectives of this project are to review and evaluate sewage treatment technologies and propose a method to improve or select appropriate technology. Sequencing batch reactor (SBR) is a part of the secondary treatment process of sewage treatment. It is fill and draw-type of activated sludge system involving a single complicated mix reactor where all steps of an activated sludge process take place. The objectives of this project are to review and evaluate sewage treatment technologies and propose a method to improve or select appropriate technology. Sequencing batch reactor (SBR) is a part of the secondary treatment process of sewage treatment. It is fill and draw-type of activated sludge system involving a single complicated mix reactor where all steps of an activated sludge process take place.

Introduction

I. INTRODUCTION

Human health and environment are mainly affected by the direct disposal of industrial and human effluents into natural resources without any treatment. Sewage treatment is necessary to reduce the toxicity of sewage and maintain a safe and healthy environment, as well as promote human welfare.

A treatment plant is necessary for an industrial process to treat wastewater. It reduces industrial water consumption and environmental pollution. A sewage Treatment Plant is a plant or installation setup that is used to purify contaminated substances. These substances may be solid, liquid and semi-solids.

India is one of the most water-stressed regions in the world, with 600 million Indians facing extreme water stress, according to a NITI Aayog report from 2018. The report warns that by 2030 water demand could be twice the existing supply which could lead to severe water scarcity for millions of people and a ~6% loss to the country’s GDP. Thus, the importance of understanding and managing our water needs and resources in an efficient manner is becoming ever more crucial. Reusing and recycling our water resources is essential in maintaining a sustainable future.

The UN Waste Water Assessment Programme report states that high-income countries treat approximately 70% of the wastewater that is generated. The ratio drops to 38% in upper-middle-income countries, 28% in lower-middle-income countries and 8% in low-income countries. This adds up to around 20% of the wastewater being treated globally.

Raigarh is a city and municipal corporation in the Raigarh district of the Indian state of Chhattisgarh and the administrative headquarters of Raigarh district. It is known for its coal reserve and power generation for the state as well as the country. With a population of just about 3,64,000, it is a rapidly growing industrial city and home to the Mohan Jute Mill, one of the oldest Jute mill in India and the only one in Madhya Pradesh before the splitting off of Chhattisgarh in year 2000. Raigarh has an average elevation of 215 meters. The Kelo River flows through the city, which is one of its primary water sources. The district ranks 7th in terms of population size. The decadal growth rate of the population of the community is 18.1%. The percentage of urban population is 16.5%, density wise the district is ranked 6th in the state. Raigarh is the most populous town with 1,50,019 persons.

The city does not have any sewerage system, and neither sewage treatment plant exists. The town does not have any particular type of drainage system. Roadside open drainages are the means of transportation of the wastewater. Also, there is no systematic and organized method to collect and treat waste from the septic tank. Overflow of septic tank effluent directly discharges to the stormwater drains, which ultimately fall into the local Nallah and finally drain out to the Kelo River. Hence complete sewage treatment plant is required to be developed.

A Sequencing Batch Reactor (SBR) Technology is the same as the activated sludge process. The only difference is, the aeration and settling phases are carried out in batch mode, one after the other in the same Tank.

A Sequential Batch Reactor Technology consists of a single Tank equipped with an inlet for raw Sewage, air diffusers with associated compressors and piping for aeration, a sludge draw-off mechanism for waste sludge, a decant mechanism to remove the supernatant after settling, and a control mechanism to time and sequence the processes.

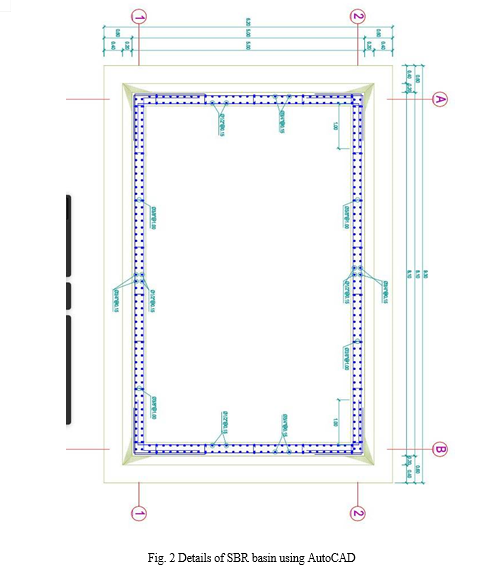

AutoCAD is a powerful tool for automating graphical work based on personal computers. It gives the user possibilities which earlier could be realized only on big and expensive computing systems: any drawing that was drawn manually can be constructed with AutoCAD now. AutoCAD is capable to perform almost any kinds of graphic works. Thus, there is a high speed and simplicity in creation a drawing and its updating that, in turn, allows reducing essentially time necessary for performance of these processes, in comparison with drawing manually.

II. LITERATURE REVIEW

Gupta et al., 2017 studied that effluent of wastewater characteristics generated from the college of engineering Roorkee. It involves studies of pH values, total solids, total suspended solids, alkalinity, hardness, acidity, chloride, chlorine, BOD, COD, DO, and turbidity. The main objective of the paper is to produce an environmentally treated effluent by using a sewage treatment plant. For selecting and designing sewage treatment systems, Engineering factors, Environmental factors, and cost considerations are important criteria.

Shrirang Vrushali, 2018 reported that Sewage treatment is the process of removing contaminants from wastewater and household Sewage, both runoffs (effluents), domestic, commercial, and institutional. It includes physical, chemical, and biological processes to remove physical, chemical, and biological contaminants. Its objective is to produce an environmentally safe fluid waste stream (or Treated Effluent) and a solid waste (or treated sludge) suitable for disposal or reuse. In this research paper, a lab-scale study was conducted to evaluate the performance of the Activated Sludge Process followed by Chlorination & Dual Media Filtration for treating Sewage and reusing the treated Sewage for various purposes such as gardening, cooling water makeup, landscape developing, toilet flushing, road washing.

Ambica, 2014 studied the water quality parameters such as pH, Alkalinity, Electrical conductivity, Chloride, Hardness, and Total dissolved solids and dissolved oxygen. The standard result of these parameters is shown in table.

Managing clean water and waste materials is a major problem for any city. By using sewage treatment plants, we can dispose of Sewage as well as reduced environmental pollution. According to the literature review, the design of a sewage treatment plant for any city depends on its population.

Sewage generation is estimated to be 80% of the total water consumption. Accordingly, the sewage treatment plant is designed for the next 25 to 30 years. In sewage treatment plants, the primary unit, secondary unit, and tertiary unit's structural design is usually done. The sewage treatment process removes up to 90% of organic matter from wastewater. The sequencing batch reactor also comes under the secondary treatment process. Researchers worldwide have reported that the various components of sewage treatment plants are screening, grit chamber, primary sedimentation tank, biological reactor, secondary clarifier, activated sludge tank, drying beds.

From the various literature, SBR is a cyclic activated sludge treatment process. It provides the highest treatment efficiency possible in a single-step biological process. SBR is a fill, aeration, settle, and decant step carried out in batches in a single basin. SBR technology required a minimum of two SBR basins. If one basin is inactive, the plant can still treat influent wastewater because of the equalization basin.

III. METHODOLOGY

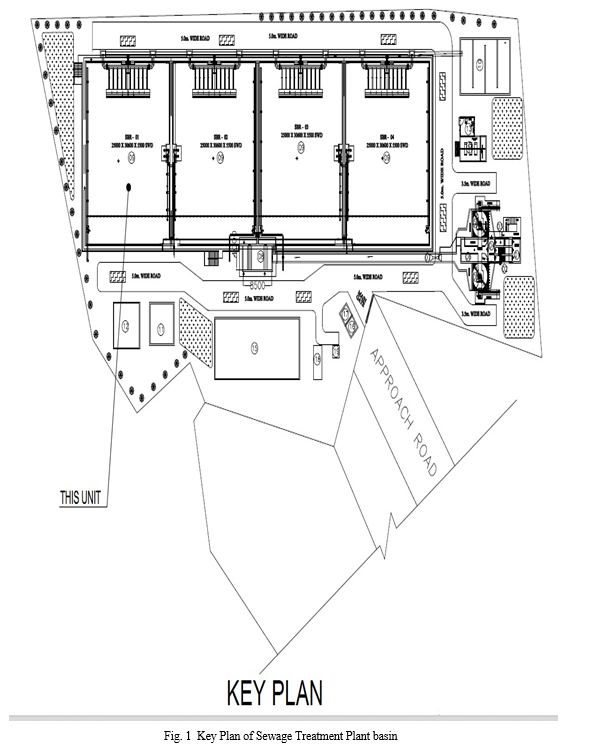

- The project methodology is to conduct a literature review and detailed survey of Raigarh city and proof check the design of the sequencing batch reactor that is being constructed.

- Based on the literature review, the project deals with the designing of STP for the population of Raigarh city.

- The STP is being constructed for around 24 MLD capacities.

- It will be ensured that the drawings of SBR shall contain all the information required to complete the project as per specification and related IS code.

- The objective of this project is to design, modeling and analyze a SBR of a sewage treatment plant using various Is code.

IV. BASIC DESIGN CONSIDERATION

The objective of a sewage collection, treatment and disposal system is to ensure that sewage discharged from communities is properly collected, transported, and treated to the required degree, in short, medium, and long-term planning and disposed-off/reused without causing any health or environmental problems.

Short term: Implies the immediate provision of an on-site system. It is an interim arrangement until the implementation of the long-term plan. Short-term plans should be formulated for a target up to5 years from the base year.

Medium-term: Implies the provision of a decentralized (non-conventional) system of collection for rapid implementation of the collection, transportation, treatment, and disposal/local reuse to avoid sporadic sewage discharges into the environment and where conventional sewerage system is not feasible. Medium-term plans should have a target of 15 years from the base year.

Long-term: Implies conventional sewage collection, transportation, treatment, and environmentally sound disposal/reuse. It encompasses the short term and medium term. Long-term plans should be formulated for a target of 30 years from the base year.

The quantity of wastewater generated, to be transported and treated will depend on population and per capita water use. Per capita water supply for domestic needs is proposed to be 135 LPCD.

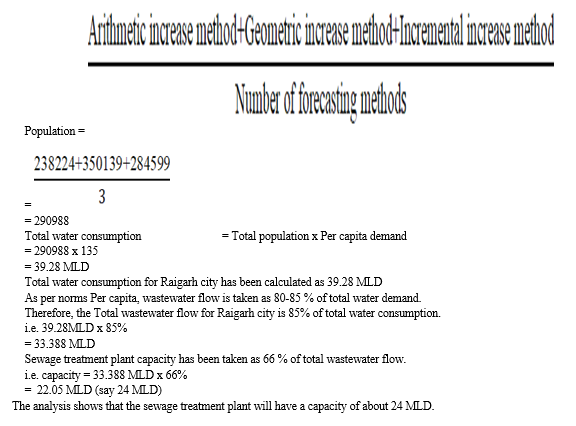

The city population is determined based on the average of the population obtained by all three methods i.e. Arithmetic increase method, Geometric increase method, Incremental increase method

Consider Base year = 2020

The design period for a sewage treatment plant is considered 15 years.

Design year = 2035

Conclusion

The version of this template is V2. Most of the formatting instructions in this document have been compiled by Causal Productions from the IEEE LaTeX style files. Causal Productions offers both A4 templates and US Letter templates for LaTeX and Microsoft Word. The LaTeX templates depend on the official IEEEtran.cls and IEEEtran.bst files, whereas the Microsoft Word templates are self-contained. Causal Productions has used its best efforts to ensure that the templates have the same appearance. The ultimate goal of sewage treatment is the protection of the environment in a manner with public health and socio-economic concerns. Since there is no proper treatment plant for sewage in Raigarh city, it is necessary to construct a sewage treatment plant of 24 MLD for the expected population of the next 15 years. The design of a sequencing batch reactor involves lots of mathematical formulas and calculations and the basin is designed to meet future expansion. In the study of the sewage treatment plant in Raigarh city, it was concluded that the city has no proper treatment plant exists. As per the current situation in the city, saving the water and making the potential reuse of the treated sewage is much necessary, the idea for the proposed treatment process will be highly beneficial for making reuse of the treated sewage in the city. Sequencing Batch Reactor is a continuous process in a batch. After the structural design calculation, it was concluded that the total effective volume of the SBR tank is 11990 m3. The considered examples show that AutoCAD was and remains powerful means of a technical drawing.

References

[1] D. of C. O. Chhattisgarh, “District Census Handbook Raigarh,” no. i, 2011, p. 283. [2] I. R. G. Census Commissioner, “1991 Census Hand Book,” p. 145, 1996. [3] T. Nadu, “District census handbook,” 2011. [4] CENSUS of India, “District Poulation,” 2001. [5] CPHEEO, “Chapter 5,” 2013. [6] D. Gupta, A. Ghildiyal, N. Rana, A. Kumar, I. Goyal, and G. Goswami, “Design and Analysis of Sewage Treatment,” vol. 2, no. 2456, pp. 30–36, 2017. [7] C. K. Shrirang Vrushali, “SEWAGE TREATMENT AND REUSE - A STEP TOWARDS WATER CONSERVATION,” Gait Posture, vol. 62, no. 2, pp. 235–240, 2018, doi: 10.1016/j.gaitpost.2018.03.005. [8] A. Ambica, “Ground water quality characteristics study by using water quality index in tambaram area, Chennai, Tamil nadu,” Middle - East J. Sci. Res., vol. 20, no. 11, pp. 1396–1401, 2014, doi: 10.5829/idosi.mejsr.2014.20.11.257. [9] S. Muttamara, “and recycling Wastewater characteristics,” Resour. Coservation Recycl., vol. 16, pp. 145–159, 1996. [10] H. A. Meena, “Design of Sewage Treatment Plant by Act Method,” Int. J. Res. Appl. Sci. Eng. Technol., vol. 7, no. 5, pp. 1399–1403, 2019, doi: 10.22214/ijraset.2019.5236. [11] H. Aswathy.M, “ANALYSIS AND DESIGN OF SEWAGE TREATMENT PLANT (STP) OF APPARTMENTS IN CHENNAI,” Int. J. Pure Appl. Math., vol. 116, no. 13, pp. 157–163, 2017. [12] B. Bhavin et al., “Study and Modification of Sewage Treatment Plant at Jaspur,” Int. J., vol. 4, no. 10, pp. 118–123, 2018. [13] R. N. Azuana and H. MohdFairuzAbdul, “A review on two different systems in municipal sewage treatment plant,” IEEE, pp. 5–9, 2017. [14] S. Shree Samal, “Design of Sewage Treatment Plant,” IOSR J. Mech. Civ. Eng., vol. 13, no. 05, pp. 25–31, 2016, doi: 10.9790/1684-1305052531. [15] P. Puspalatha and P. Kalpana, “Environmental Science?: An Indian Journal Design Approach for Sewage Treatment Plant?: A Case Study of Srikakulam,” vol. 12, no. 9, pp. 1–7, 2016. [16] E. G and R. V.M, “Analysis and Design of Sewage Treatment Plant: A Case Study Atnagore,” Int. Res. J. Multidiscip. Technovation, vol. 1, no. 6, pp. 543–552, 2019, doi: 10.34256/irjmtcon79. [17] S. Vigneswaran, M. Sundaravadivel, and D. S. Chaudhary, “M SC PL O E – C EO M SC PL O E –,” 2007. [18] Zhu, M. Wu, J. Yang, C. Wei, and B. Zhang, “Effect of sluge retention time on nutrient removal by a humus soil sequencing batch reactor,” 2009 Int. Conf. Energy Environ. Technol. ICEET 2009, vol. 3, no. 062307039, pp. 290–293, 2009, doi: 10.1109/ICEET.2009.535. [19] L. Tianyou, T. Zhongde, Y. Xiaoyuan, C. Guanwen, and W. Qiongfang, “Based on statistical analysis of construction and operation status of urban sewage treatment plants in Guizhou Province,” Proc. - 2014 5th Int. Conf. Intell. Syst. Des. Eng. Appl. ISDEA 2014, pp. 243–246, 2014, doi: 10.1109/ISDEA.2014.60. [20] O. Daniel and N. B. Onyedikachukwu, “Design of Sequencing Batch Reactor (SBR) Treatment Plant for Abattoir Wastewater (A Case of Apa Mmini Stream),” J. Eng. Res. Reports, vol. 11, no. 1, pp. 15–21, 2020, doi: 10.9734/jerr/2020/v11i117050. [21] V. Tare and P. Bose, “Compendium of Sewage Treatment,” pp. 1–60, 2009. [22] CPHEEO, “Chapter 1: Introduction,” Man. Sewerage Sew. Treat. Syst., pp. 1.1-1.17, 2013, [Online]. Available: http://www.ncbi.nlm.nih.gov/pubmed/15003161%5Cnhttp://cid.oxfordjournals.org/lookup/doi/10.1093/cid/cir991%5Cnhttp://www.scielo.cl/pdf/udecada/v15n26/art06.pdf%5Cnhttp://www.scopus.com/inward/record.url?eid=2-s2.0-84861150233&partnerID=tZOtx3y1. [23] CPHEEO, “Manual on Sewerage and Sewage Treatment Systems,” no. November 2013. [24] CPHEEO, “Chapter 4: Design and construction of sewage pumping stations and sewage pumping mains,” Man. Sewerage Sew. Treat. Syst., pp. 4.1-4.31, 2013. [25] IS 456, “Concrete, Plain and Reinforced,” Bur. Indian Stand. Dehli, pp. 1–114, 2000. [26] IS:800-2007, “IS?: 800 - 2007, Indian standard code of practice for general construction in steel,” Bur. Indian Stand. New Delhi, 2007. [27] IS 3370:2009 (Part-1), “Code of PracticeConcrete Structures for the Storage of Liquids - Part 1?: General Requirements,” 2009. [28] IS 3370:2009 (Part-2), “Code of Practice Concrete structures for the storage of liquids - Part 2: Reinforced concrete structures,” 2009. [29] Lin, R.; Li, Y.; Yong, T.; Cao, W.; Wu, J.; Shen, Y. Synergistic effects of oxidation, coagulation and adsorption in the integrated fenton-based process for wastewater treatment: A review. J. Environ. Manag. 2022, 306, 114460. [30] Sakr, M.; Mohamed, M.M.; Maraqa, M.A.; Hamouda, M.A.; Aly Hassan, A.; Ali, J.; Jung, J. A critical review of the recent developments in micro–nano bubbles applications for domestic and industrial wastewater treatment. Alex. Eng. J. 2021 [31] Soares, A. Wastewater treatment in 2050: Challenges ahead and future vision in a European context. Environ. Sci. Ecotechnol. 2020, 2, 100030. [32] Li, S.; Show, P.L.; Ngo, H.H.; Ho, S.-H. Algae-mediated antibiotic wastewater treatment: A critical review. Environ. Sci. Ecotechnol. 2022; [33] Abunada, Z.; Alazaiza, M.Y.D.; Bashir, M.J.K. An Overview of Per- and Polyfluoroalkyl Substances (PFAS) in the Environment: Source, Fate, Risk and Regulations. Water 2020, 12, 3590. [34] Amr, S.S.A.; Abushammala, M.F.M.; Al Maskari, T. Recent Advances of Nanoremediation Technologies for Soil and Groundwater Remediation: A Review. Water 2021, 13, 2186. [35] Ang, T.-H.; Kiatkittipong, K.; Kiatkittipong, W.; Chua, S.-C.; Lim, J.W.; Show, P.-L.; Bashir, M.J.K.; Ho, Y.-C. Insight on Extraction and Characterisation of Biopolymers as the Green Coagulants for Microalgae Harvesting. Water 2020, 12, 1388. [36] Deborah A. Mitta , Patricia L. Flores. User Productivity as a function of AutoCAD Interface design [J]. Applied Ergonomics, 26(6):387-395, 1995 [37] Greg MacGeorge. Start automating AutoCAD today with basic VBA [J]. Inside AutoCAD, 14(2):8-11, 2006 [38] J.P.Hao,Y.L.Yu and Q. Xue.A maintainability analysis visualization system and its development under the AutoCAD environment [J]. Journal of Materials Processing Technology, 129(1-3):277- 282, 2002

Copyright

Copyright © 2024 Jaishankar Gabel, Dr. Rakesh Kumar Pandey. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET62597

Publish Date : 2024-05-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online